Quartz Crystal Blanks

We offer a wide selection of quartz substrates from various fused quartz supplies. Our engineering is available to assist in the selection of substrates and make recommendations if requested. In order to make sure the parts we make will meet the customer’s expectations we maintain a very stringent quality control procedure and observe ISO specifications. Product “traveler” documentation records and our Quality Control Manual are available for inspection by the customer. At the end of the production line it is becoming a standard procedure to have the appropriate part identification laser scribed onto the surface before it will go through final cleaning, inspection, and packaging processes. We can ship the products to any destination and by any method requested by the customer, or we can suggest methods and carriers that are economical and safe.

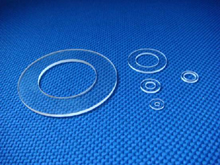

AT or BT-CUT Round Blanks

|

Specifications |

Example

|

Available

|

|

ZZ’ ZZ’ Angle: |

35°23′ ± 3′

|

± 1′ , ± 2′ , ± 3′

|

|

Diameter: |

Æ 8.0 + 0-0.05mm

|

Æ 4.5 – Æ 9mm

|

|

Frequency:

|

20MHz

|

3.0 – 100M

|

|

Quartz:

|

Q3 2.0×106

|

|

|

Others:

|

At Customer’s request |

|

AT or BT-CUT Strip Blanks

|

Specifications |

Example

|

Available |

|

ZZ’ ZZ’ Angle: |

35°14′ ± 3′

|

± 1′ , ± 2′ , ± 3′

|

|

Frequency:

|

20MHz

|

3.5 – 60M

|

|

Quartz:

|

Q3 2.0×106

|

|

|

Others:

|

At Customer’s request |

|

AT or BT-CUT Wafers

|

Specifications |

Example

|

Available |

|

|

ZZ’ ZZ’ Angle: |

35°25′ ± 3′

|

± 1′ , ± 2′ , ± 3′

|

|

|

Diameter:

|

X·Z : 10 x 22mm

|

10 x 24.5mm

|

|

|

Thickness:

|

0.3-0.35mm

|

0.2-1.10mm

|

|

|

Parallelism:

|

0-0.03

|

0-0.03mm

|

0-0.05mm

|